Nowadays, efficiency and accuracy are paramount in industrial logistics. Rugged handheld barcode scanners have become vital tools for enterprises seeking to streamline operations, increase productivity, and preserve operational integrity in tough conditions. This article explores the features, applications, benefits, and key considerations for selecting rugged handheld barcode scanners.

Understanding Rugged Handheld Barcode Scanners

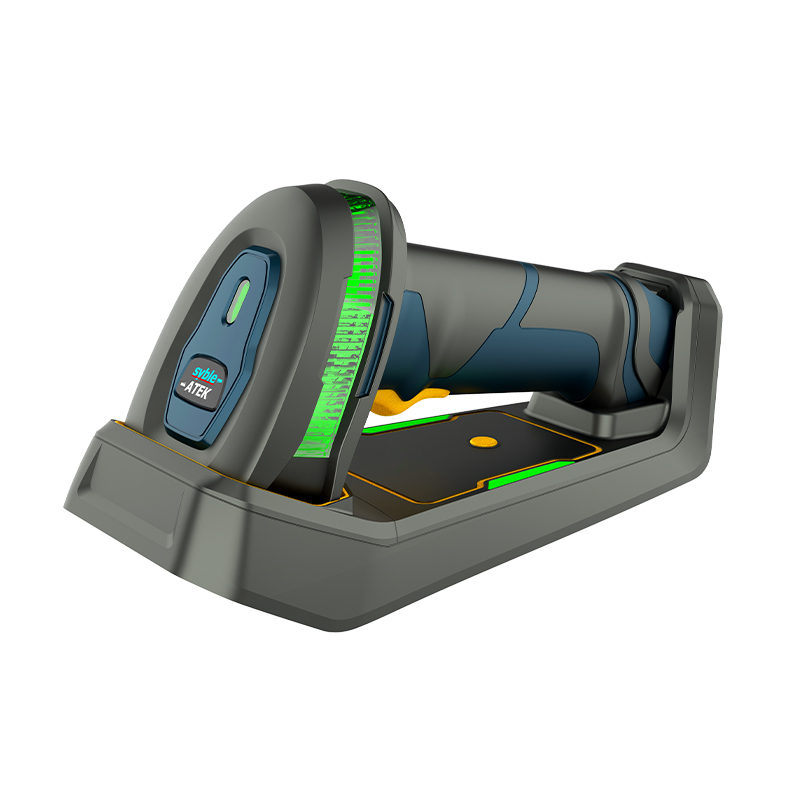

Rugged handheld barcode scanners are specifically engineered to resist tough industrial settings. Unlike standard barcode scanners, these devices are constructed with robust materials that provide resistance to impacts, moisture, dust, and extreme temperatures.

Key Characteristics

Durability: Rugged scanners are designed to withstand drops and exposure to environmental elements and are frequently rated for drop resistance and ingress protection (IP) against dust and moisture.

Performance: These scanners offer high-speed scanning capabilities and can read various barcode symbologies, ensuring quick data capture.

Connectivity: Many rugged scanners come equipped with multiple connectivity options, including Bluetooth, Wi-Fi, and USB, facilitating seamless integration with existing systems.

Battery Life: Long-lasting batteries are essential for uninterrupted operation during long shifts, minimizing downtime.

Ergonomics: Designed for comfort, rugged scanners often feature ergonomic grips and user-friendly interfaces, making them suitable for extended use.

Applications and Use Cases

Rugged handheld barcode scanners are versatile tools utilized across various sectors, including:

Warehousing and Logistics

These scanners help warehouses manage inventory more efficiently by allowing for quick and precise scanning of commodities during the storage, shipping, and receiving operations. They help track inventory levels and ensure timely order fulfillment.

Manufacturing

In manufacturing settings, rugged scanners streamline production processes by tracking work-in-progress, managing inventory, and ensuring product traceability. They play a crucial role in maintaining operational efficiency and quality control.

Field Service

Field service technicians rely on rugged handheld scanners to capture data on-site, manage service orders, and ensure accurate billing. Their durability allows them to function effectively in outdoor environments.

Retail and Healthcare

In retail, rugged scanners enhance checkout efficiency and inventory management. In healthcare, they are used for patient identification, medication management, and tracking medical supplies, ensuring accuracy and compliance.

Warehouse Handheld Barcode Scanner

Benefits of Rugged Handheld Barcode Scanners

Investing in rugged handheld barcode scanners offers numerous advantages for businesses:

Increased Productivity

The speed and reliability of rugged scanners streamline scanning processes, leading to improved productivity and operational efficiency. Businesses can focus on essential tasks by devoting less time to data entry and inventory management.

Reduced Downtime

Rugged scanners are designed to withstand harsh environments, minimizing the risk of equipment failure or damage. This durability translates to reduced downtime and maintenance costs, allowing operations to run smoothly.

Enhanced Data Accuracy

High-performance scanning technology ensures accurate capture of barcode data, significantly reducing errors. This accuracy is vital for inventory management and order fulfillment, leading to improved customer satisfaction.

Long-Term Cost Savings

While the initial investment in rugged scanners may be higher than standard models, their durability and reliability result in long-term cost savings. Businesses benefit from fewer repair and replacement costs, making robust scanners an economical solution.

Rugged Handheld Scanner for Warehouses

Key Considerations for Choosing Rugged Handheld Barcode Scanners

When selecting a rugged handheld barcode scanner, several factors should be taken into account:

1. Environment Compatibility

Evaluate the specific environmental conditions where the scanner will be used. Consider factors such as temperature extremes, exposure to moisture, and the likelihood of drops or impacts.

2. Scanning Requirements

Determine the types of barcodes that need to be scanned (1D, 2D, etc.) and the scanning distance required. Choose a scanner that meets these specifications to ensure optimal performance.

3. Connectivity Needs

Assess the connectivity options needed for seamless integration with existing systems. Ensure that the scanner supports the necessary protocols for data transfer.

4. Battery Life

Consider the typical duration of work shifts and select a scanner with a battery life that can support continuous operation without frequent recharging.

5. User Experience

Prioritize scanners with ergonomic designs and intuitive interfaces. This enhances usability and comfort, particularly for employees who will be using the device for extended periods.

Conclusion

Rugged handheld barcode scanners are essential tools for businesses operating in industrial logistics. Businesses may make informed judgments about scanners by understanding their characteristics, applications, and benefits.