In today's fast-paced logistics and supply chain ecosystem, warehouses are constantly grappling with the dual pressures of escalating e-commerce demands and globalized supply chains. To meet these heightened customer expectations, barcode scanning technology, especially advanced models like the Syble AK-9000, is proving indispensable. In this deep dive, we'll explore the essential role of barcode scanners in warehouse operations, focusing on efficiency gains, accuracy improvements, and strong compliance adherence, which collectively streamline warehouse efficiencies to unprecedented levels.

Improved Inventory Management

Effective inventory management is the foundation of every successful warehouse business. Barcodes give a consistent and systematic method for tracking inventory goods. Each product is allocated a unique barcode that includes important information such as the product name, SKU (Stock Keeping Unit), serial number, batch number, and other pertinent information. When items are received, picked, or shipped, warehouse staff can simply scan the barcode to update the inventory system in real time. This not only eliminates the need for manual data entry but also ensures that inventory records are accurate and up-to-date. With improved visibility into inventory levels, warehouses can make informed decisions regarding stock replenishment, storage allocation, and order fulfillment, ultimately optimizing their inventory management processes.

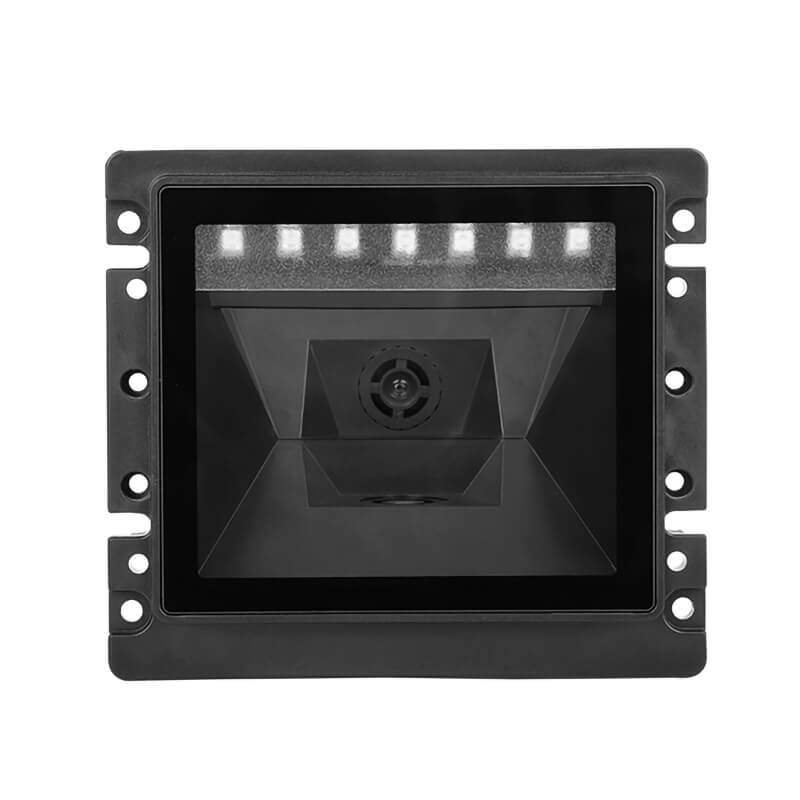

SYBLE Barcode Scanner For Inventory

Increased Efficiency

Time is of the essence in the warehouse environment, where every second counts. Barcode scanners help streamline warehouse operations by automating tedious tasks and minimizing unnecessary delays. Instead of manually recording product information or searching through shelves for specific items, warehouse staff can quickly scan barcodes to retrieve accurate data in a matter of seconds. This greatly accelerates procedures like as receiving products, identifying inventories, selecting items for orders, and preparing shipments for delivery. As a result, warehouses can handle higher volumes of orders with greater efficiency, meeting customer demands and reducing turnaround times.

Enhanced Traceability

Traceability is essential for ensuring product quality, safety, and compliance with regulatory requirements. Barcodes play a crucial role in enabling end-to-end traceability throughout the supply chain. By scanning barcodes at various stages of the logistics process, warehouses can track the movement of products from the point of origin to the final destination. This involves tracking things as they are delivered by suppliers, kept in the warehouse, chosen for orders and dispatched to clients. In the case of a product recall, regulatory compliance checks, warehouses equipped with advanced scanning solutions like the Syble AK-9000 can quickly trace impacted products back to their source, pinpoint the exact cause of the issue, and initiate effective corrective measures. This not only helps mitigate risks but also protects consumers, enhances brand reputation, and ensures compliance with industry standards and regulations.

Advanced AIDC Equipment From Syble

Error Reduction

Manual data entry is inherently prone to errors, which can have costly consequences in the warehouse environment. Mistakes in picking, shipping, and inventory can lead to stockouts, overstocking, customer complaints, and financial losses. Barcode scanners assist in reducing these risks by reducing the human mistakes associated with manual data entry. By scanning barcodes, warehouse staff can accurately capture product information and update inventory records with precision. This reduces the likelihood of errors, improves order accuracy, and enhances overall operational efficiency. With fewer errors to contend with, warehouses can deliver a higher level of service to customers, improve inventory accuracy, and optimize their resource utilization.

Scalability

As warehouses grow and expand their operations, they need scalable solutions that can accommodate increasing volumes of products, orders, and shipments. Barcode scanning technology is highly scalable, making it well-suited for warehouses of all sizes and complexities. Whether handling hundreds or thousands of SKUs, barcode scanners can adapt to the evolving needs of the warehouse environment. As new products are introduced, inventory levels fluctuate, or order volumes increase, barcode scanners can scale accordingly, providing the flexibility and agility needed to support growing business demands. Furthermore, barcode scanning technology is interoperable with a wide range of hardware and software platforms, allowing warehouses to maximize existing infrastructure investments while smoothly integrating new technologies as needed. This scalability assures that warehouses will continue to function efficiently and effectively.

Conclusion

In conclusion, barcode scanners are indispensable tools for modern warehouses seeking to improve efficiency, accuracy, and overall productivity. As the demands of the supply chain continue to evolve, choosing a high-quality barcode scanner is an important thing. SYBLE, as a premier barcode scanner supplier, specializing in various barcode scanners fit to different applications. If you are interested in it, please browse our website for more details!